GOOD VIBRATIONS:

VIB TURNING TECHNOLOGY

Essentially, vibration and natural frequencies are undesirable in mechanical engineering. This is achieved in part through the selection of materials, which in our case involves making the machine base out of polymer concrete.

Furthermore, with the help of finite element calculations and simulations in the design process, an attempt is made to prevent machine elements from vibrating in an uncontrolled manner.

In a very extensive range of tests, in collaboration with the competence center responsible for chip-cutting production (KSF in Schwennigen), it was established that it is possible to influence the chip-cutting process through the application of modulated vibration. This improves process stability when turning and drilling.

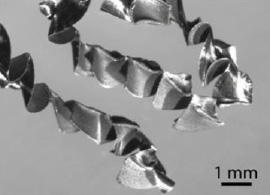

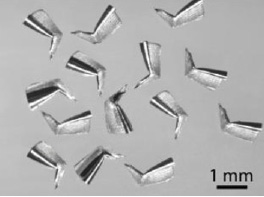

Controlled chip-cutting can be achieved through modulated amplitudes. Here, swarf is no longer an unknown parameter. Instead, it can be influenced individually, without modifying the tool geometry. The parallel-axis amplitudes reduce the cutting force and this reduces the thermal load on the cutting blade.

Improvement in the mechanical properties of implants through the use of stronger and harder materials, resulting in long, thread-like swarf preventing optimum cooling from the coolant while swarf interfere with the action of the counter-spindle. Vib Turn can be used to improve these unstable processes.